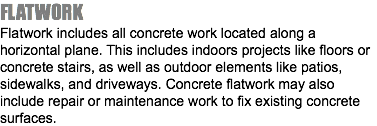

HMI self-performs structural concrete work on sophisticated projects ranging from schools to showroom floors, to retaining walls, commercial buildings and more. Our crew’s precision work, absolute attention to quality and detail, and our commitment to meeting important deadlines and project specifications makes HMI a valued partner in construction projects locally and nationwide. We also use a laser screed for placing concrete to ensure precision and the highest quality construction.

After establishing a comprehensive plan for each project, HMI will lead the project team in executing that plan efficiently and effectively. The experience of our staff is integrally valuable in helping the team to determine the best methods, techniques and practices at each step. Our clients want and receive quality cost-effective construction services that provide a high level of accountability and facility functionality. Here are some of the services we offer.

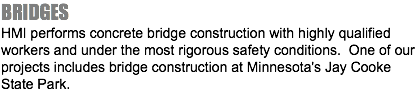

HMI utilizes the latest technology with the Somero S485 Laser Screed system. Why use laser screed? Screeding concrete has come a long way from the basic 2x4. Laser screed has set new standards for accuracy and productivity. Our screed uses lasers to identify and place concrete automatically to specified elevations. The laser screed also combines both placement and strike off in a single step with heads that incorporate plow, auger, and vibrator, enabling it to spread fresh concrete and set it precisely in a single pass.

The laser screed allows our crews to work faster and flatter without the need for rakers. It allows our crews to screed in any direction and screeds on elevated slabs or on grade. It is 3D capable for contour paving as well.

The two year project to construct the 135,000 square foot new high school addition consisted of classrooms, gymnasiums, theatrical spaces, dining areas, musical rooms and an auditorium. The 24,000 square foot elementary school addition included classrooms and a new gymnasium. Cast-in-place foundations, slabs, structural floor toppings and poured concrete stair systems were all completed by HMI.

The rehabilitation of the historic baseball complex included new artificial turf, stadium lighting, brick restoration and exterior site improvements. An extensive amount of concrete flatwork outside the 1st and 3rd base lines was completed by HMI. These areas are now used for player warm-up and spectator events. Decorative concrete was also installed near the entry to the stadium.

Following the summer of 2012 flooding in Duluth, Congdon Boulevard suffered slope, storm pipe, and guardrail failures at several locations. HMI was tasked by the city with the repairs needed to make sure these failures were properly addressed and fixed. The scale of the project was extensive and the finished product was as fully functional as it is visually appealing with the natural beauty of Duluth's lakeshore.